Process Automation Systems and Tools

KonsOM SKS offers process automation and production automation services for steel and mining industries.

Automation plays an ever increasing role in today’s industry. This is why the choice of automation tools is very important. Development and supply of comprehensive process systems, as well as process control and optimization systems constitute one of the major areas of what we do. We offer a wide range of comprehensive process automation and optimization tools.

Development of a proper process control system is a complex engineering task which requires a variety of information technologies and specific solutions to be employed.

The comprehensive systems developed by the company are based on the classical three-level model:

- lower level – field instrumentation;

- intermediate level – basic process automation (controllers);

- upper level – process control (SCADA systems).

The lower level consists of field instrumentation such as sensors, actuators, and control panels. Lower level instrumentation is responsible for physical measurements and signal conversion, as well as for equipment control based on signals received from controllers.

The control level is comprised of high-efficiency distributed I/O programmable logical controllers.

The upper level comprises operator workstations and servers. It is responsible for centralized control of the process.

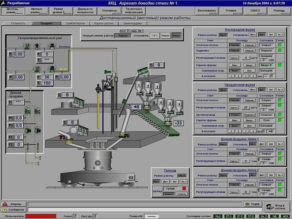

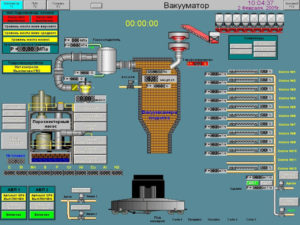

A common SCADA system implemented at the upper level performs the following functions:

- data acquisition from instruments and controllers;

- online process visualization;

- generation and display of critical trends;

- remote manual and automatic control of the process;

- automatic diagnostics to check the statuses and modes of the plant components; alarms and warnings;

- generation and activation of interlocks in case of out-of-range parameters;

- operator support in the form of tips and help menus;

- keeping logs of parameters, events, commands and notices of completion;

- operator action logging for further analysis of process performance and emergencies;

- the opportunity to change the operating procedure or the system algorithm;

- sending information to the workstations in the form of mnemocircuits, graphs or tables while defining user access rights;

- generation of process status reports.

The lower level and the intermediate level are built with state-of-the-art software and hardware products supplied by leading manufacturers from Russia and abroad (Siemens, Schneider Electric, Bernecker&Rainer, ABB, Omron and others), whereas SCADA systems are developed based on the software products by Siemens WinCC, Schneider Vijeo Citect, WonderWare InTouch, Bernecker&Rainer and others.

Our specialists provide a full scope of services involved in the development and implementation of automation solutions at the Customer’s premises:

- inspection;

- preparation of SOW;

- elaboration of engineering documentation following national standards (GOST);

- selection and supply of necessary component;

- controller programming & development of SCADA systems;

- assembly and installation of network, server and control cabinets;

- supervision;

- commissioning;

- training;

- warranty and post-warranty service