Stationary Vibration Monitoring System, Vibration Monitoring

- Description

- Components

Stationary Vibration Monitoring Systems are vastly used in power, oil and gas, chemicals, steel and transport industries.

Having its own non-destructive testing lab and an extensive expertise in the field, KonsOM SKS would be happy to offer a full range of services related to the introduction of Stationary Vibration Monitoring Systems at your site.

Purpose

Stationary Vibration Monitoring Systems are designed to monitor vibration on the equipment and its rotating parts in order to detect any faults and perform corrective actions to prevent poor performance, reduced service life or failures.

This type of vibration monitoring systems includes vibration sensors, matching amplifiers, as well as data processing and storage units with a continuous data acquisition functionality.

Functions

- Collects data from the vibration sensors, the controller and related process control systems.

- Implements an online control of any vibration parameters.

- Creates the logs (or databases) of vibration parameters and other process parameters.

- Displays warnings when abnormal vibration is detected.

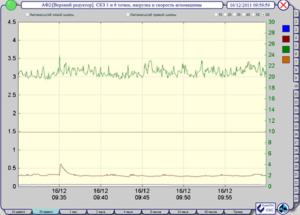

- Builds real-time and history vibration trends.

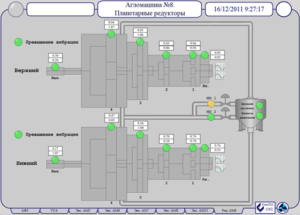

- Displays data in a user-friendly form (mnemocircuits).

- Integrates with the existing process control systems.

The integration platform is based on the PARADIGMA package, which performs the common functionality of data acquisition, processing, storage and transmission (to the user workstations).

The vibration monitoring station is responsible for displaying the vibration and process data in the form of mnemocircuits. The station is based on the Flash technology and the Thin Client technology, and does not require any additional software as all screens are accessible as common web pages via standard browsers (for example, Internet Explorer).

As agreed with the Customer, any other data visualization technology or commercial software products (like Simatic Win CC and Wonderware InTouch) can be adopted.

Advantages

- Early detection of faults.

- Increased reliability and extended equipment life.

- Extended mean time to repair.

- Reduced failures.

- Consistent maintenance planning.

We provide a full scope of services involved in the implementation of Stationary Vibration Monitoring Systems at the Customer’s site, including:

- investigation;

- preparation of SOW;

- elaboration of engineering documentation following national standards (GOST);

- selection and supply of necessary equipment;

- controller programming and application software development;

- construction and installation (supervision);

- commissioning;

- training;

- warranty and post-warranty service.

Components

- Vibration sensors permanently installed at key points.

- A programmable controller.

- A server and user workstations.

- System software.

Software

The system software is comprised of two components:

- Process Data Integration Platform;

- Vibration Monitoring Station.