Quality Control Systems (based on PAK 6.8) for Materials and Products

- Description

- Components

Quality Control Systems are designed to analyze the chemical compositions of large amounts of bulk materials (e.g. ore transported on a conveyor belt) based on X-Ray Fluorescence (XRF) technology.

The systems are based on the proprietary Production Analysis System (PAK 6.8) encompassing a conveyor analyzer, a lift control system, a load monitoring system and a specialized software.

This solution is designed for mining, processing and steel industries.

Functionality

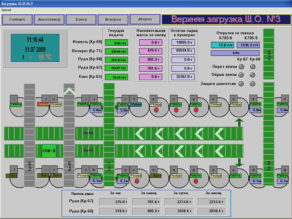

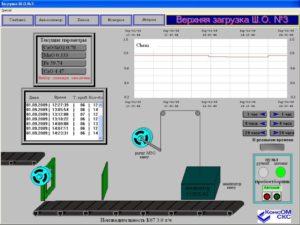

- Collecting, processing and storing data coming from the Analyzer and related process control systems.

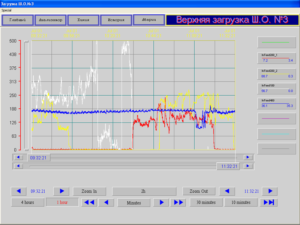

- Online monitoring of the chemical composition of material transported on the conveyor belt.

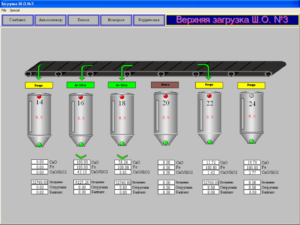

- Calculating the average concentrations of elements in bulk material (piles and bins).

- Dosing of consumables for obtaining the specified quality of the final product.

- System event and alarm detection and logging.

- Out-of-range parameter indication.

- Real-time and archive trends.

- User-friendly visualization of process data (mnemocircuits).

- Generation of reports.

Description

The X-ray fluorescence analyzer identifies and measures the concentrations of chemical elements in the material on a conveyor belt. The characteristic radiation, which carries the information about the concentrations of elements in the material and which is produced by an X-ray tube, is detected by a silicon drift detector cooled by a Peltier element. The measured data are stored in the analyzer memory before being transferred to the PAK programme.

These data serves as baseline data for calculating the average concentrations of elements in piles and bins, as well as for dosing the consumables in order to obtain the specified quality of the final product.

Benefits

- Increased accuracy and reduced time of identifying the chemical compositions of materials and products.

- Optimized real-time control of material flow and blending.

We provide a full range of services related to the implementation of material and product quality control systems, including:

- inspection and sample testing for identifying if PAK can be practicable for the Customer;

- preparation of SOW;

- creation of a mathematical model suitable for a particular environment;

- elaboration of documentation per national standards, i.e. GOST (including all tie-ins);

- supply of equipment;

- installation and commissioning;

- personnel training;

- stable operation control: hardware, software and technological support;

- warranty and post-warranty service.

For more information about PAK and how it can be implemented at your site:

You can call us:

- +7 982 3000 900 (MTS). Contact person – Oleg Tishin, Project Leader.

- +7 982 3000 109 (MTS). Contact person – Andrey Usherov, Scientific Coordinator, Head of R&D Center, Ph.D. in Engineering.

- +7 982 3000 912 (MTS). Contact person – Anatoly Lednov, Key Account Manager, Ph.D. in Engineering.

Email us:

info@konsom.ru

Or visit our office:13 Zhukova Str., Magnitogorsk.

At our office we can show you a presentation of the product, answer all your questions and, most importantly, you can see an example of the actual application of PAK at MMK Sintering Plant.

For us to be able to say if PAK can be practicable in your case, you are kindly offered to fill in the following forms:

PAK Components

- XRF probing station which determines the chemical composition of the material

- Floating support and load monitoring system ensuring damage protection in case of drastic flow changes

- Specialized software

Probing Station Capabilities

- Radiation Source: Low-energy X-ray tube

- Detector type: SDD detector with a Peltier element

- Operational temperature range: -20…+35оС

- Enclosure protection: IP65

- Range of measured elements depending on lump size:

- Up to 200 – 400 mm: From Ca – Ti to Mo

- Up to 30 – 50 mm: From S – Cl to Mo

- Up to 1 mm: From Si to Mo

- Max. number of elements measured at the same time: 8

Software

Functionality:

- SCADA system.

- Process monitoring workstation (a web client).

- Consumables control workstation (if needed).

- Reporting module.