Transport Tracking System (RFID-based satellite-aided vehicle tracking system)

- Description

- Components

We offer an RFID-based solution designed for vehicle tracking at industrial sites with extensive premises. Such systems are used for visual control and real-time tracking of railway cars, locomotives, torpedo cars, etc. moving between different production shops or parked at dead-ends for loading or unloading. The main purpose behind satellite-aided vehicle tracking systems is to enable a quicker access to a full and accurate information about the railway transport for timely decision-making.

Functionality

- Data collected from readers located in control points.

- Identification of tags, railway cars or trains, railway transport routes or locations.

- Monitoring of railway trains.

- Monitoring of railway cars in or out of the loading/unloading position.

- Monitoring of travel time, downtime, loading/unloading time.

- Integration with plant-scale monitoring systems for information about the transported goods.

- Integration with weighing systems for the status of a vehicle or railway transport (loaded/empty).

- Maintaining a reference database (tags, readers, all kinds of vehicles and railway transport, locations of tags, etc.).

- Testing the system and checking the devices.

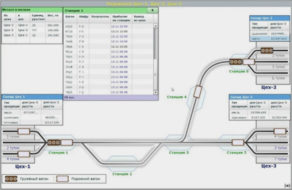

- User-friendly visualization of process data (mnemocircuits).

- Generation of reports.

Benefits

- Quicker access to a full and accurate information for timely decision-making.

- Enhanced performance.

- Reduced downtime.

Our specialists provide a full scope of services involved in the implementation of Transport Tracking Systems at the Customer’s premises, including:

- inspection;

- preparation of SOW;

- elaboration of documentation per national standards, i.e. GOST;

- selection and supply of necessary components;

- development of applied software;

- installation (supervision);

- commissioning;

- personnel training;

- warranty and post-warranty service.

Components

- RFID tags, i.e. devices capable of storing and transmitting data. Tags may contain various data. What kind of data needs to be saved is determined by the developer based on the Customer’s requirements.

- RFID readers, i.e. devices that write and read the tag data.

- Main server and user workstations.

- Network infrastructure – It integrates the identification devices and the system server.

- Software – It comprises a set of programs which build the algorithm of the system.

When developing our Transport Tracking Systems we use the TagMaster equipment from Sweden.

Installation

All transport units are equipped with RFID tags, a receiver and a transmitter. RFID tags are attached to a transport unit two tags on each side. RFID readers are installed in control points along the railway tracks and at loading/unloading stations. They can be installed in steel boxes with 3 mm thick walls or on poles. According to the railway safety rules, the height of a box or a pole at different land slopes may not exceed the height of the nearest railway track with the smallest slope by more than 1.25 m from the top of rail. The minimum distance between the rails and the box with an RFID reader shall be 0.8 m. All RFID readers and tags are registered in the reference database.

Software

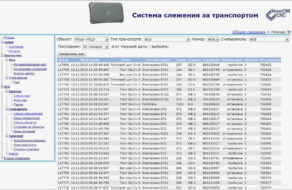

- RFID Database

- Reference Data, Status Monitoring and Diagnostics Workstation:this workstation is designed to collect, process and store data about system object identification, train routes, etc. It is also responsible for maintaining reference data, checking the system for faults and checking the operability of the system devices.

- Railway Transport Tracking Mnemocircuit:this mnemocircuit is designed for visualization of data about the railway train locations and routes, as well as about the goods and the presence of steel products.